PolyJet technology

PolyJet technology is a powerful additive manufacturing method that produces smooth, accurate prototypes, parts and tooling. With 16-micron layer resolution and accuracy as high as 0.1 mm, it can produce thin walls and complex geometries using the widest range of materials.

FDM technology

FDM Technology is a powerful Stratasys-patented additive manufacturing method. FDM builds concept models, functional prototypes and end-use parts in standard, engineering-grade and high-performance thermoplastics. It’s the only professional 3D printing technology that uses production-grade thermoplastics, so parts are unrivaled in mechanical, thermal and chemical strength.

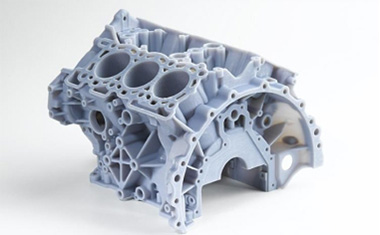

Metal/Composite printing technology

Metal and Composite material printing is used to create high-precision mechanically and thermally resilient components. In this process, fine metal powder is melted locally by a high-energy fiber laser. The material solidifies after cooling. This patented process ensures a significant reduction in stress when manufacturing very large components.

Only imagining the final product is difficult with our printers, creating them is a piece of cake.